The process of Silicon Nitride etch is used in manufacturing of certain Semiconductor devices, the etch rate of Silicon Nitride depends on the concentration of Phosphoric acid and temperature. These process factors must be controlled precisely to achieve the highest possible temperatures and water concentrations. The TTN Series bath system contains all the time proven features and benefits of the TT Series bath with the addition of a PID control and cooling system to accommodate Nitride Etch/Strip applications with high temperature Phosphoric Acid. Automatic DI water replenishment to maintain consistent acid/water ratio, efficient reflux cooling, and precision heat control allow for improved etch uniformity and selectivity.

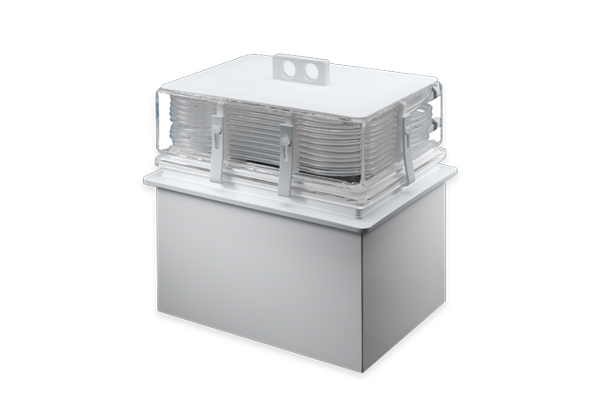

Tiger Tanks™ Constant Temperature Baths

Designed for today’s advanced deep-submicron wafer processing, PCT’s Tiger Tank Constant Temperature Bath construction exceeds the most stringent demands of today’s wafer fabrication facilities. Tiger Tanks deliver unequaled performance, stability, reliability, longer life, and incorporate improved safety features.

• A time-proven, rugged, high efficiency heater features low watt densities for extended life. The Tiger Tank heater is intimately contacted to the vessel and covers a larger area of the vessels external surface for greater heat transfer efficiency and temperature uniformity.

• The superior insulation used in Tiger Tanks further enhances the overall thermal efficiencies of the unit, reducing external heat generated in operation and reducing electricity consumption.

• Standard fire-retardant polypropylene housing construction, FM 4910 enclosures available

• An improved and proprietary flange / seal design further extends bath life and protects against capillary action induced leakage that would normally cause corrosive heater failure

• Tiger Tanks include dual redundant over temperature sensor protection; a thermocouple and thermal switch bonded to the outer wall of the vessel for optimal safety

• Proprietary Solid-State Power Supply & Control System delivers high reliability and precision

The TTN Series bath system contains all the time proven features and benefits of the TT Series bath with the addition of a control and cooling system to accommodate Nitride Etch/Strip applications with high temperature Phosphoric Acid. Automatic DI water replenishment to maintain consistent acid/water ratio, efficient reflux cooling, and precision heat control allow for improved etch uniformity and selectivity.

- High reliable quartz tank design

- Hydroseal washer standard on all TTN baths for longer RTV seal life

- Manual or Auto-lid configurations (side and end configurations)

- 190°C temperature operation; higher temperatures available on custom baths

- Liquid Level Sensors

- Dual Panel flow meter for DI water drip and cooling water control

- RTD Temperature Sensors

- TC and Snap Switch overtempature devices